Everbal

Sustainable development with Everbal

Everbal is one of the few integrated companies that performs end-to-end paper manufacturing, from the production of paper through to its transformation into finished products. We fully master each step along the way and keep track of everything about the materials and ingredients found in each reel of paper – even the sequencing of the manufacturing steps – to guarantee full traceability for our transformed paper products.

Recycled papers mean responsible growth

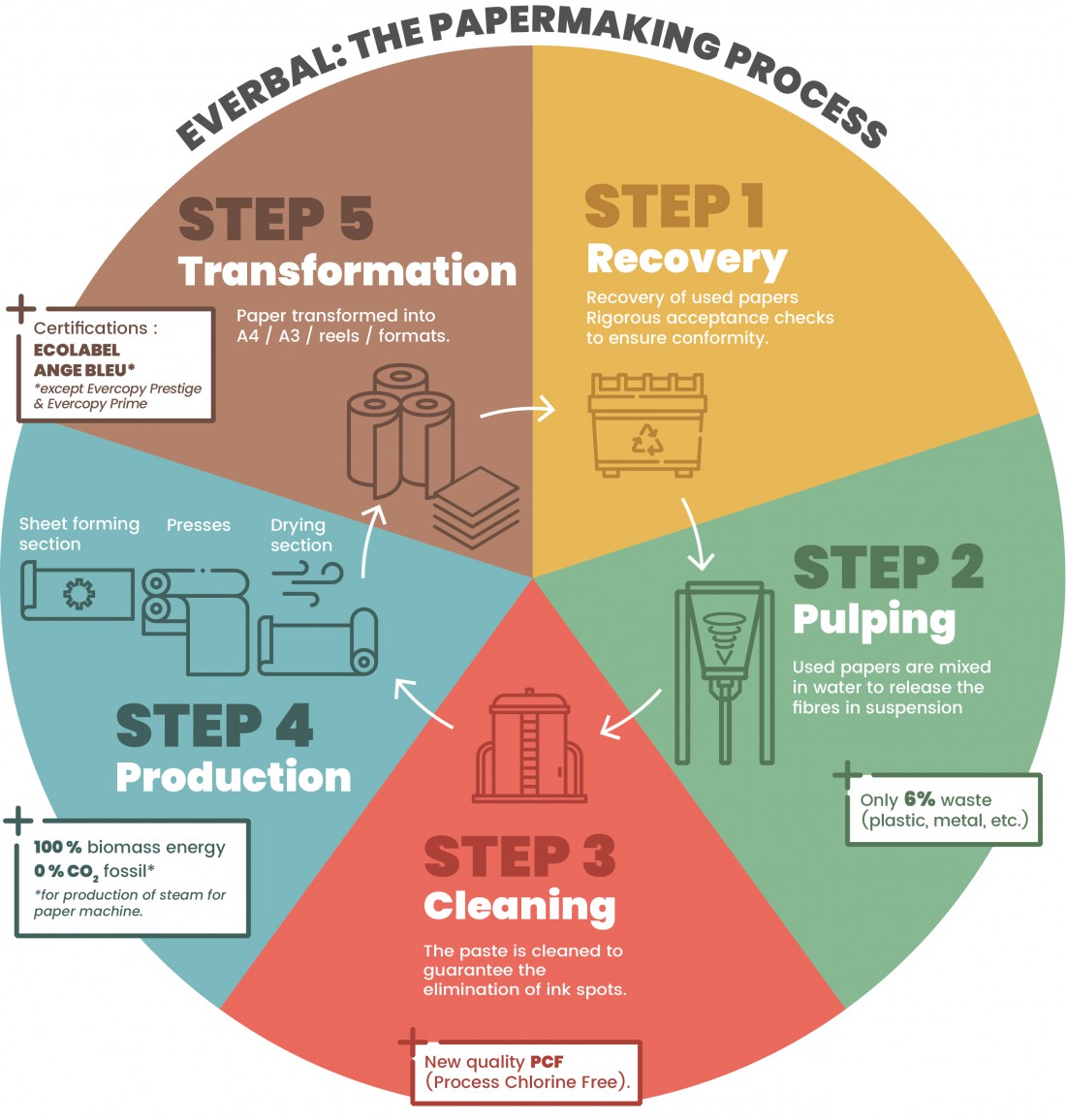

Everbal: the papermaking process

Step 1

Recovery

Recovery of used papers

Rigorous acceptance checks to ensure conformity.

Step 2

Pulping

Used papers are mixed in water to release the fibres in suspension

Only 6% waste (plastic, metal, etc.)

Step 3

Cleaning

The paste is cleaned to guarantee the

elimination of ink spots.

New quality PCF

(Process Chlorine Free).

Step 4

Production

100% biomass energy

0% CO2 fossil*

*for production of steam for paper machine.

Step 5

Transformation

Paper transformed into

A4 / A3 / reels / formats.

Certifications:

ECOLABEL

ANGE BLEU*

*except Evercopy Prestige

& Evercopy Prime

A model based on the circular economy

Used papers are recovered from local sources – as are the woodchips we use to produce steam to power our paper machines. This solution means less energy and transport needs.

Our on-site production processes are based on the total reuse of recovered papers with no deinking, optical brighteners, or chlorine treatment.

This approach offers a major advantage: reduced water consumption, because the plant operates in a closed loop. What’s more, Everbal has its own water treatment plant, which can eliminate nearly all the materials from the effluents and discharge clean water into the river. The sludge extracted from this treatment is reused as an agricultural amendment, thereby helping to improve the soils in the region. Our model, in which recycled papers are processed through a circular economy, generates almost no waste. Year after year, water consumption and effluent wastes continue to decrease thanks to the on-going cooperation between our manufacturing teams, QSE department and water treatment plant managers. In 2010, the average water consumption to produce 1 tonne of paper was 30 m3, whereas today it is less than

12 m3/tonne.

A frontrunner in the choice of facilities – 100% biomass

It was in 2009 that Everbal made the bold decision to use biomass, with a boiler generating 5.2 MW of power. Combined energy production was used at the time, as some heating oil was still required to supply the paper machine with steam. Encouraged by the success of this initial venture, Everbal installed a second biomass boiler at the plant in 2013. It was more powerful than its predecessor, generating 8.9 MW. Through this investment, Everbal was able to completely do away with fossil fuels and use this new source of energy to meet all its needs. The company can now proudly boast production performance that is 100% biomass.

Cradle-to-gate life cycle analysis

To take its sustainable development approach one step further, Everbal undertook an analysis of its entire life cycle. The analysis covered the entire production chain, from the obtaining of raw materials through to product sales, using a “cradle-to-gate” approach. The functional unit selected for this analysis was the production of one tonne of paper made from recycled papers at the Everbal plant.

The CO2 emissions from the production of one tonne of paper made from 100% recycled papers is roughly

283 +/- 64 kg-CO2 eq. The steps that produce the most emissions are the use of chemical products, 37%, the production of water vapour, 20%, and the consumption of fuel during transportation, 17%.

283

± 64 kg CO2-eq

- electricity

- packaging

- water

- steam production

- chemical products

- transport

- discharge of waste

Total CO2 emissions per process, kgCO2e/tonne of paper

(ACV OMNEGY – Papeteries de Clairefontaine – 2022)

Everbal produces roughly

283 kg of CO2 eq emissions for the production of one tonne of paper

Everbal uses approximately 12 m3 of water per tonne of produced paper

For the production of one tonne of paper, Everbal requires roughly 622.8 kWh